Product Implementation Cycle

Evaluation Period

TYNE provides the optimal solution.

- Fill in basic information survey.

- TYNE consultant conducts interviews via phone/on site to understand needs and expectations.

- TYNE provides initial quotation after evaluation.

- TYNE provides case demonstration for further explanation of optimization.

- If case demonstration is as the client expected, the two parties sign contracts and begin the project.

Implementation Period

Establishment of project organization and further actions.

- Client appoints a contact person for the project.

- TYNE provides online materials and online consultation/onsite consultantion.

- How to carry out data manual and automatic uploads/machine connection?

- How to define control items & relevant setting?

- How to begin monitoring?

- Implement Out of Control Action Plan (OCAP).

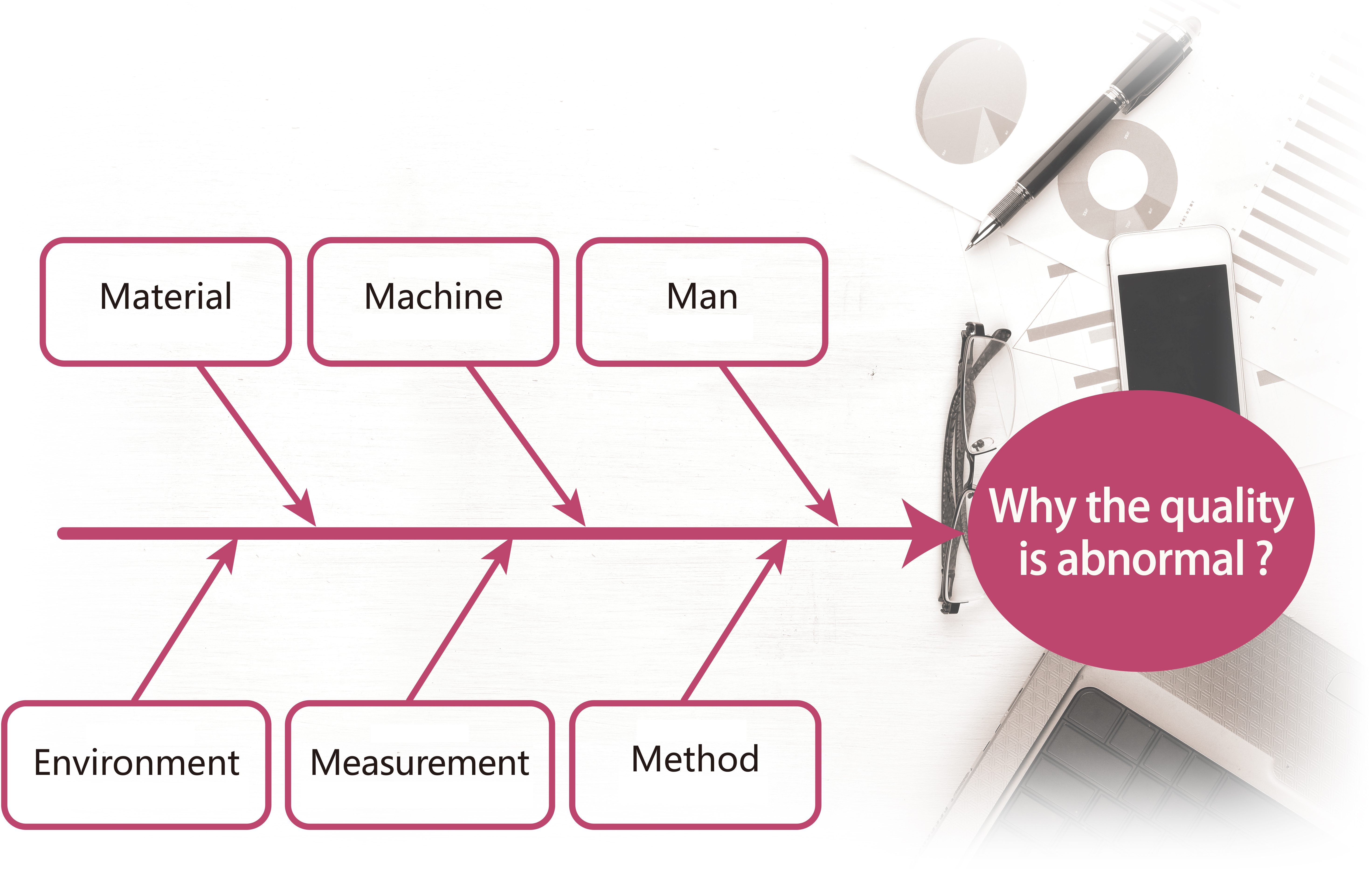

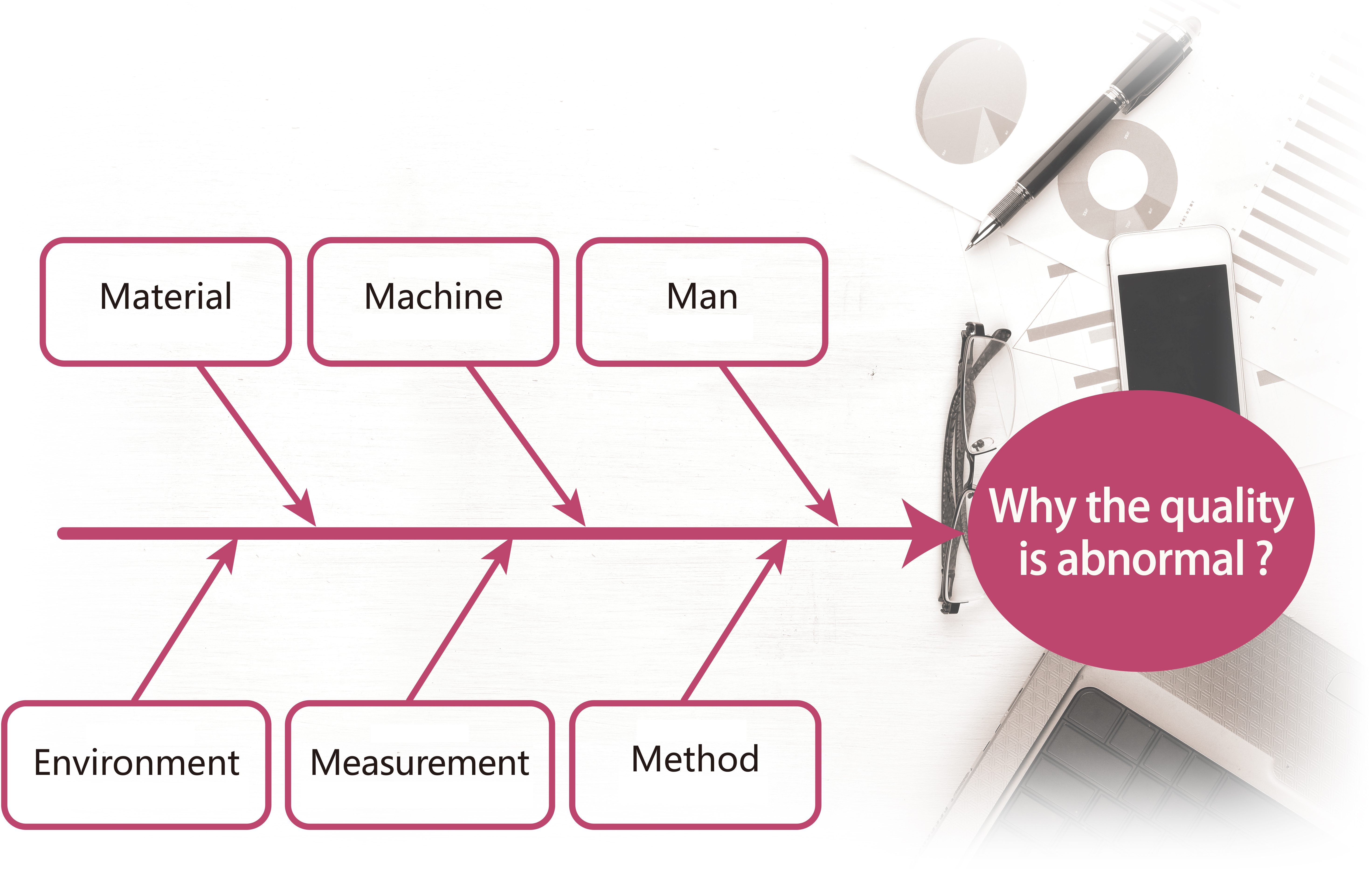

Maturation Period

Realization of organizational change.

- Include more items into control: 5M1E

- Man

- Machine

- Material

- Method

- Measurement

- Environment

- Review and draft improvement plans.

Harvest Period

Enterprize Value Up.

- After a period of quality control, the facility can experience outstanding progress.

- Satisfy the inspection needs from clients and other parties.

- Monitor the supply chain and reduce the risk of recalls, greatly reducing anomalies and scraps.

- Minimize manufacturing costs and improve product quality.

- Improve employee work efficiency and enable management to be informed within the shortest period of time.

- Maximize knowledge management within a company.