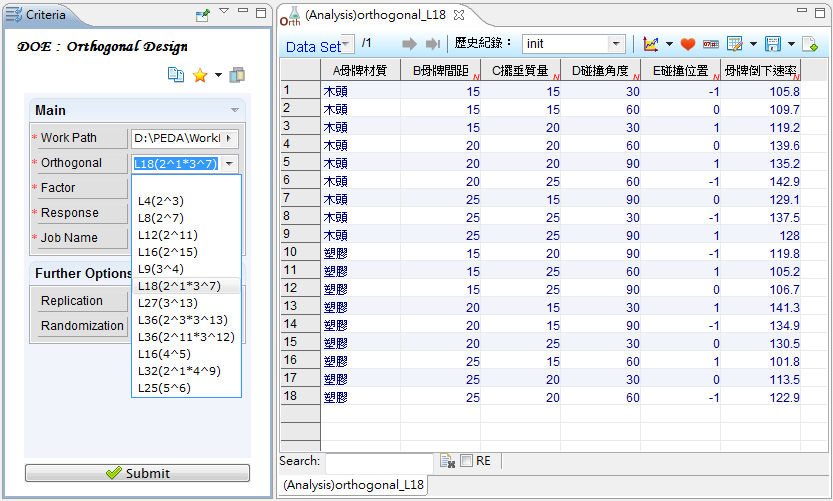

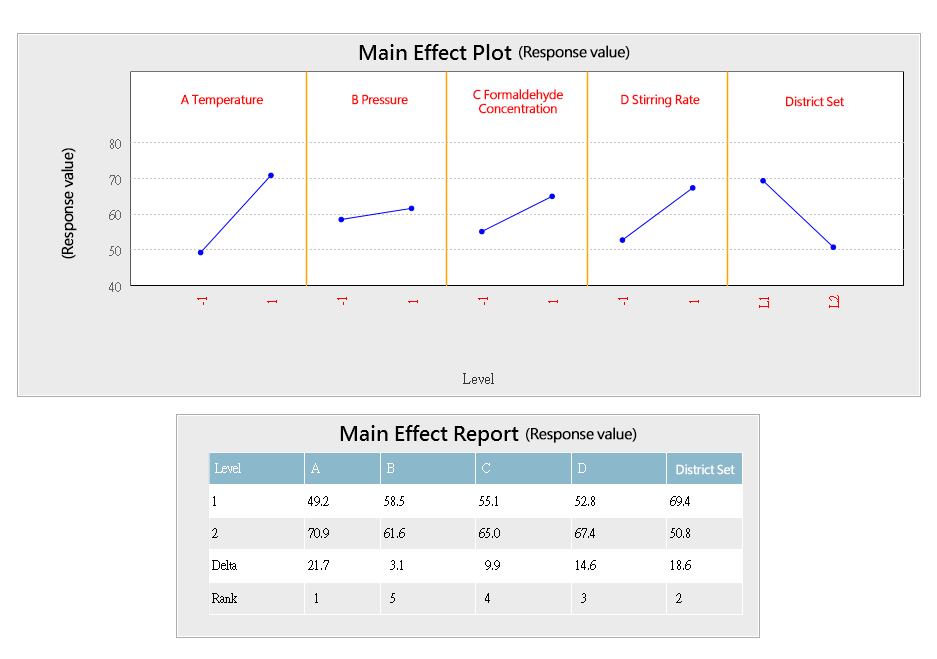

An experiment is a series of tests. It is the process of us intentionally changing the setting values of input variables in a system in order to observe the reason of output value changes and trends when carrying out these tests. And the design of experiments (DOE) is a systematic method that arranges the combination of conditions in an experiment through statistical methodologies to get reasonable experimental data more efficiently and to increase the reliability of analytical results. Let’s say we are interested to know which material can product a product with the highest hardness. In this experiment, the input variables are the “materials” whereas the output values are “hardness of a product”. The output values that we are interested in are called “raw responses”, the input variables that may affect the responses are called “factors”, and the setting values of a factor are called “levels”. The goal of DOE is to design good test conditions so that the actual factor can be identified from the various potential factors and a level that yields the response closest to the expected value can further be identified. Whether it is to shorten the development cycles of new products or to improve the manufacturing process in order to enhance the quality of products, experiments play a crucial role. Efficient experiment are developed through the design of experiments to explore key parameters that affect product characteristics, realizing the goals of wise cost management, process variation reduction, and yield rate improvement.